Formosa Pharmaceuticals Technology

Technology Advantages|APNT® nanoparticle formulation platform

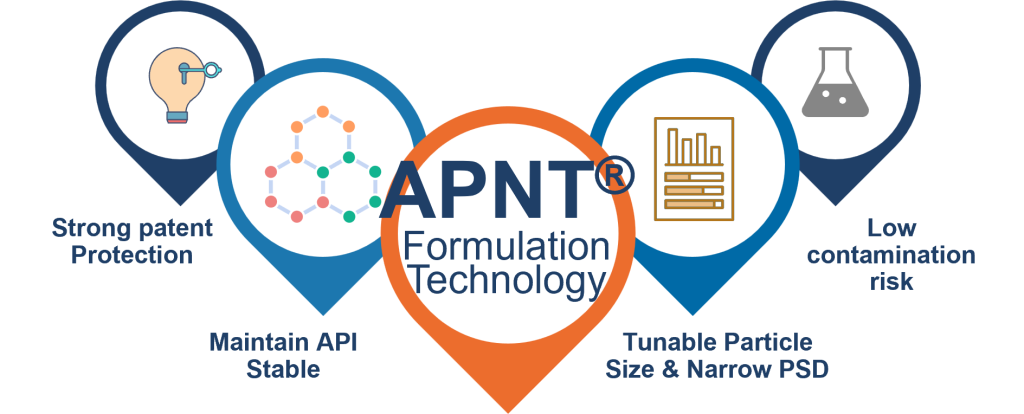

APNT® is an innovative and breakthrough technology compared with other particle size reduction platforms:

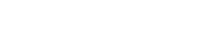

How does APNT® work ?

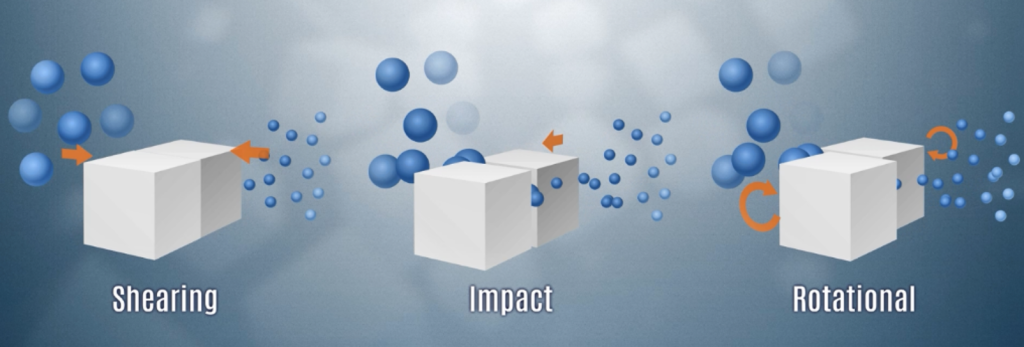

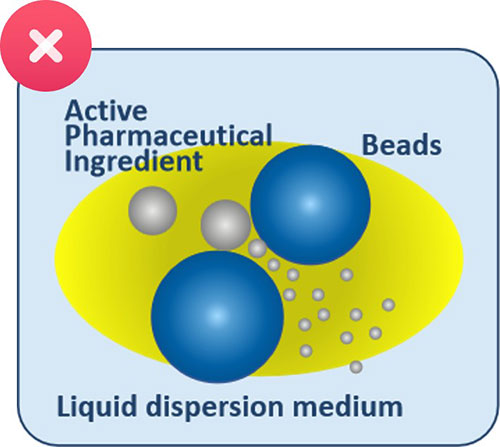

APNT® does not employ metal or plastic “beads” and therefore avoids contamination derived from fragmentation from bead collision and grinding. APNT® products have high purity, as it utilizes salts or sugars for milling, which can remain as part of the final formulation.

APNT® nanoparticle formulation technology

Beads Milling

APNT® Technology vs. Other Particle Size Reduction Platforms

| Key features | APNT® Technology | Other Particle Size Reduction Platforms (Beads-Milling, NanoEdge™, Cryomilling) | |

|---|---|---|---|

| Aseptic Filtration is possible | * Narrow particle size distribution and the particle size of APNT nanolized API can be less than 200nm to pass aseptic filter (0.2 micron). | ||

| Tunable particle size & narrow particle size distribution |

* Difficult in tuning particle size

* NanoEdge™ has broad particle distribution . |

||

| Preservation of crystal structure | * Cryomilling: amorphization of material from crystal cracking at low temperature | ||

| Adequate operational temperature |

* Beads-Milling generates high temperature which may affect API.

* Cryomilling requires extremely low temperatures. |

||

| Free of solvents and harsh additives |

* Use of organic solvents that may remain in final product and present possible toxicology or allergen risk

* Beads-Milling use of harsh additives that remain in final product |

||

| Low contamination risk | * Beads-Milling has higher contamination risk from beads. | ||

| All excipients are GRAS level | * APNT®: All excipients are GRAS (Generally Regarded As Safe) | ||

APNT® Can help your asset by